Locate

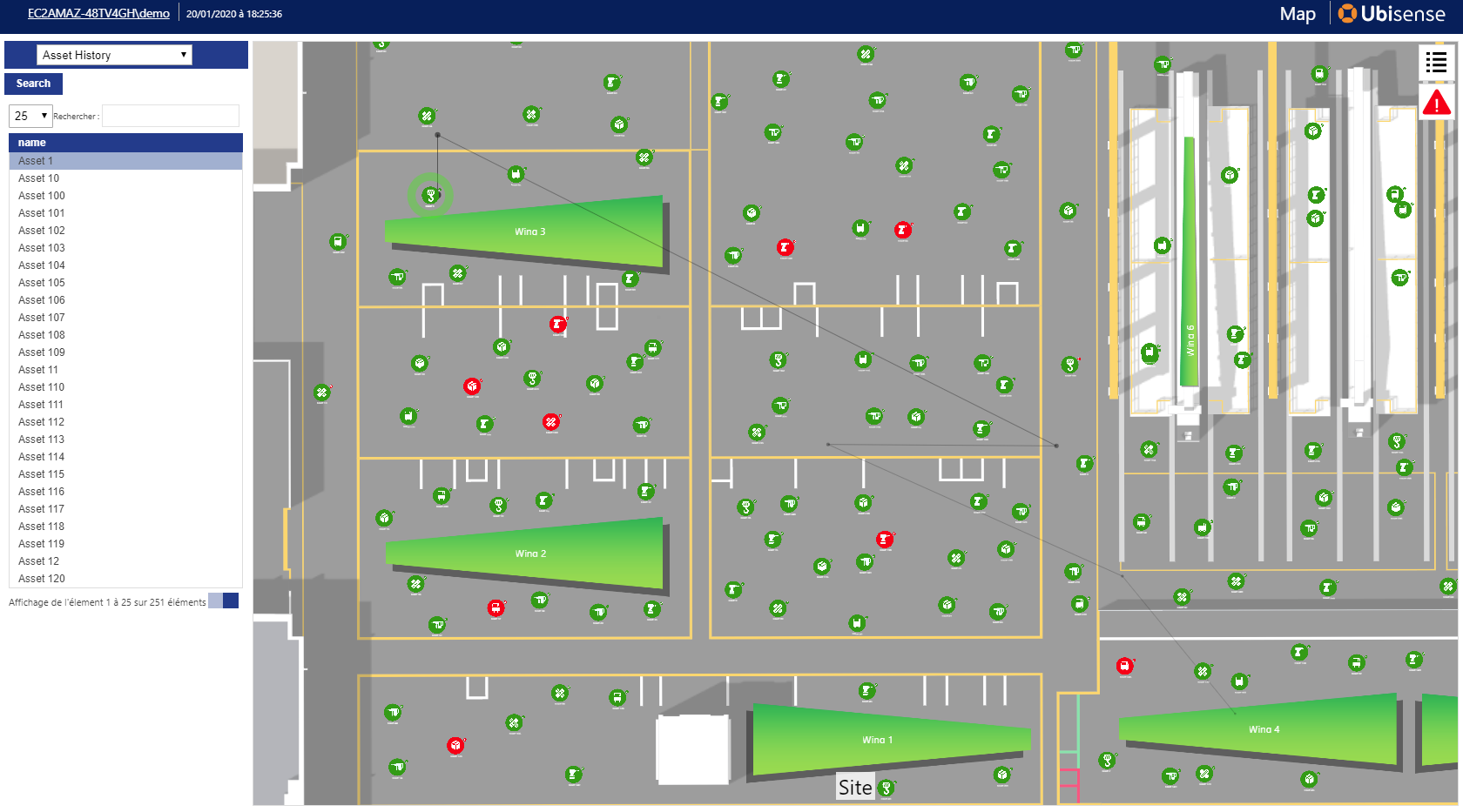

- Instantly find tools with customizable searches and an easy-to-use, browser-based map to reduce wasted search time.

- Improve process efficiency by correctly staging tools and equipment for your processes.

Manage

- Create alerts for tools based on status or location, such as tools overdue maintenance, stored incorrectly or roaming outside of designated zones.

- Use dashboards to measure tool utilization over time and within spaces, and ensure adherence to maintenance or calibration schedules.

Locating Tools

Complex, manual processes depend on the availability of the right tools and equipment, in the right place at the right time. Often tools are staged incorrectly or not returned to storage areas, putting them at risk of being lost or damaged.

Ubisense Tool Management reduces wasted search time and helps coordinate the correct staging of equipment.

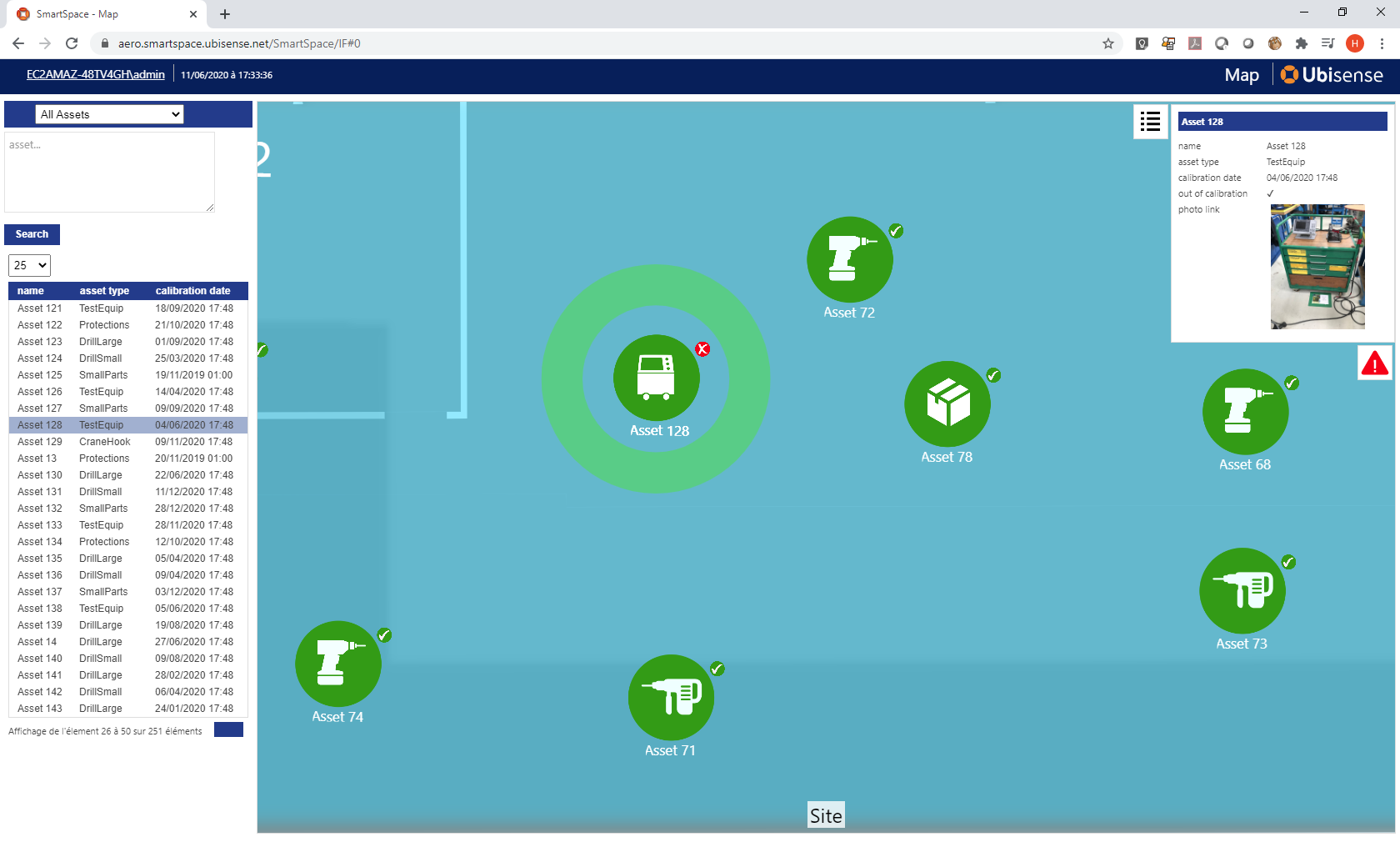

- Quickly find tools on a digital map of your facility

- Create searches based on tool location and status

- Easily see the real-time location and status of all tools using RTLS software.

Track Tool Status and Usage

The use of high-value shared equipment can be uncoordinated, causing increased costs and errors from inefficient or incorrect use of equipment.

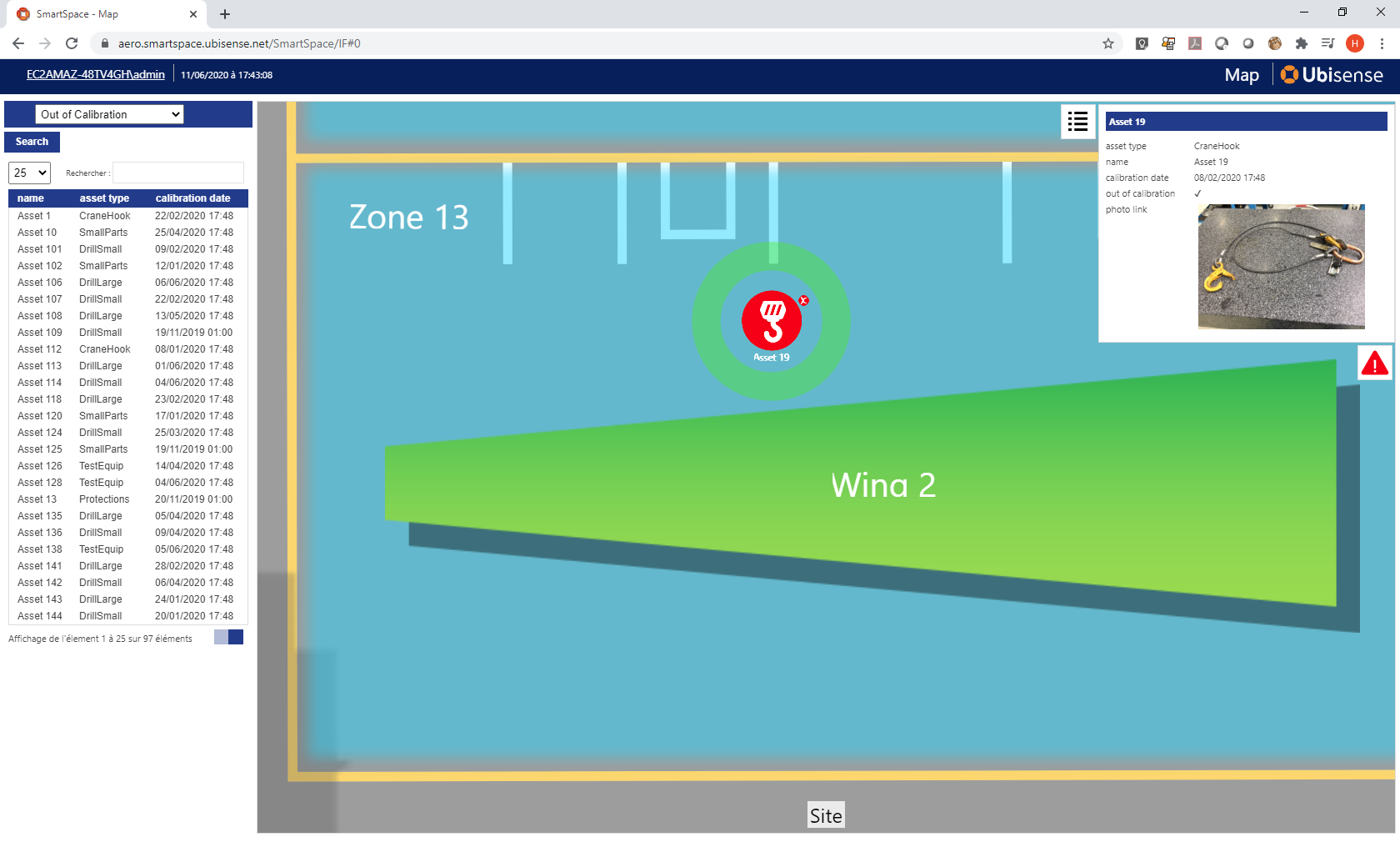

Ubisense Tool Management can ensure important maintenance and calibration schedules are met and tools are staged and used correctly, improving quality and utilization.

- Easily create alerts for tools or equipment due (or overdue) maintenance or calibration but still in use

- Use dashboards of actual tool use overtime and within defined spaces to identify better ways to stage, manage and coordinate equipment

- Trigger maintenance based on actual tool usage to reduce costs and improve quality

Automate Tool Audits

Ubisense Tool Management can automate and error proof the check-in, check-out procedures for tools and ensure operations are protected against Foreign Object Damage (FOD).

Error proof tools with automated tool check-in, check-out based on real-time location of tools in storage areas

Easily and quickly complete end-of-shift tool audits by taking a real-time inventory of the location of equipment on the shop floor or in storage

Set alerts for potential FOD based on misplaced or missing tools

Included as standard

Optional

Why Ubisense

Ubisense is proud to work with leading organizations around the globe, helping improve the management of tools and equipment, using a wide variety of proven, real-time location system technology to deliver the following outcomes:

- Elimination of search-time waste

- Prevention of critical equipment flight-risk or Foreign Object Damage (FOD)

- Increased productivity and reduced process cycle time

- Reduced capital and operational costs through better resource utilization

HEAD OFFICE (UK)

Ubisense Limited

St Andrew’s House

St Andrew’s Road

Chesterton

Cambridge, CB4 1DL

United Kingdom

+44 1223 53 5170

NORTH AMERICA

Ubisense America LLC

1630 Welton Street, Suite 1000E

Denver, CO 80202

United States

+1 720 549 7553

EUROPE

Ubisense GmbH

Klaus-Bungert-Straße 5B

40468 Düsseldorf

Germany

+49 211 2297330

Ubisense SAS

52 Boulevard De Sébastopol

75003 Paris

France

+33 1 83 79 06 82

JAPAN

Ubisense Japan

Rakuten Crimson House

1-14-1 Tamagawa

Setagaya City Tokyo

158-0094 Japan

+81 3 4577 8372