SOFTWARE

SmartSpace®

SmartSpace® is a highly-configurable software platform that tracks the real-time location, interaction and status of both people and objects in physical spaces. SmartSpace® benefits a wide variety of industries, making their operations more profitable, transparent, and safe.

What can you do with SmartSpace?

Gain Visibility

Find and track assets in real-time on an interactive map featuring automated alerts and configurable dashboards.

Optimize Systems

Monitor the movement of assets through defined process stages, identify bottlenecks and errors, and correct inefficiencies.

Automate Tasks

Directly control connected devices, automate processes, and prevent unauthorized or unsafe use of equipment.

Use Any Location Data

Easily integrate and combine a broad array of location and identification sensing technologies, including our industry leading Ubisense Dimension4 UWB.

Select the best sensing technology for the use case, including but not limited to:

- Real-Time Location Systems (RTLS) such as third party Ultra-Wideband (UWB) and Bluetooth Low-Energy (BLE) tags, anchors and beacons

- Optical Laser and Vision systems for millimetre-level accuracy

- GPS for extended outdoor, wide-area coverage

- RFID and barcode for zonal, low cost or high-volume asset tracking

Use Any Location Data

Easily integrate and combine a broad array of location and identification sensing technologies, including our industry leading Ubisense Dimension4 UWB.

Select the best sensing technology for the use case, including but not limited to:

- Real-Time Location Systems (RTLS) such as third party Ultra-Wideband (UWB) and Bluetooth Low-Energy (BLE) tags, anchors and beacons

- Optical Laser and Vision systems for millimetre-level accuracy

- GPS for extended outdoor, wide-area coverage

- RFID and barcode for zonal, low cost or high-volume asset tracking

Real-Time AI Rules Engine

Develop custom business logic for your processes using a drag and drop interface. Monitor and detect important events using real-time location sensor data and inform people, update systems of record or directly control devices to ensure process stay on track.

Real-Time AI Rules Engine

Develop custom business logic for your processes using a drag and drop interface. Monitor and detect important events using real-time location sensor data and inform people, update systems of record or directly control devices to ensure process stay on track.

Reporting & Dashboards

Build and customize process and KPI reports from large volumes of historical and real-time data.

Highlight process inefficiencies and give decision makers valuable business insights into performance, trends and previously hidden processes.

Reporting & Dashboards

Build and customize process and KPI reports from large volumes of historical and real-time data.

Highlight process inefficiencies and give decision makers valuable business insights into performance, trends and previously hidden processes.

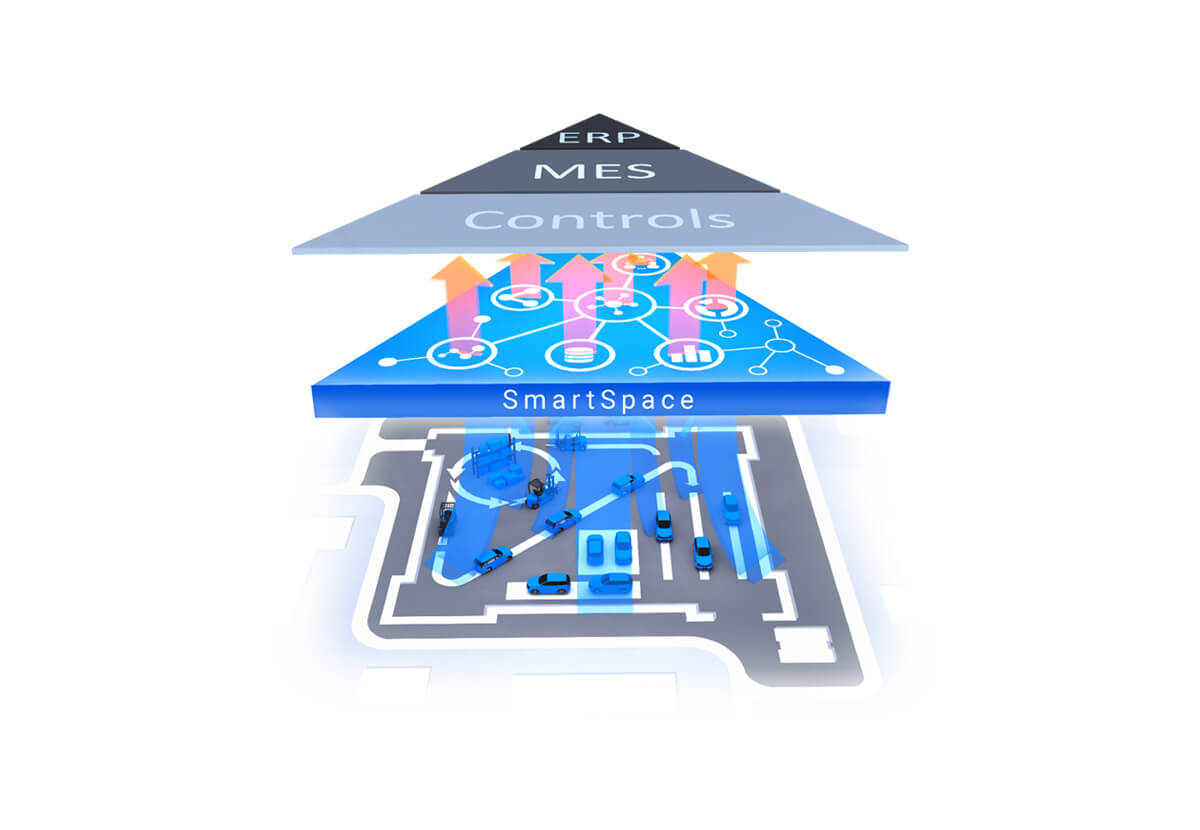

Application Integration

Exchange real-time asset location and identification data with existing business systems such as ERP and MES.

Extensible APIs support integration via various interfacing technologies including REST services, .NET, and direct RDBMS integration.

Keep your systems-of-record (SOR) up to date with what is actually happening in the real world at all times.

Digital Process Twin

Create a rich digital-twin of your physical processes, including the real-time location, movement and interaction of people and things within defined spaces.

Turn thousands of unstructured spaces and events into a language that can be processed by the rules engine to monitor, detect and control activity that is off plan.

Digital Process Twin

Create a rich digital-twin of your physical processes, including the real-time location, movement and interaction of people and things within defined spaces.

Turn thousands of unstructured spaces and events into a language that can be processed by the rules engine to monitor, detect and control activity that is off plan.

Works in the Real World

Ubisense has thrown more than 100 years of worth of development time into SmartSpace®, not just to make it the most configurable and easy to integrate location platform available, but to make sure it works where and when you need it.

SmartSpace is consistently chosen by people that what to visualize, control and improve even the most complex, mission-critical processes.

HEAD OFFICE (UK)

Ubisense Limited

St Andrew’s House

St Andrew’s Road

Chesterton

Cambridge, CB4 1DL

United Kingdom

+44 1223 53 5170

NORTH AMERICA

Ubisense America LLC

1630 Welton Street, Suite 1000E

Denver, CO 80202

United States

+1 720 549 7553

EUROPE

Ubisense GmbH

Klaus-Bungert-Straße 5B

40468 Düsseldorf

Germany

+49 211 2297330

Ubisense SAS

52 Boulevard De Sébastopol

75003 Paris

France

+33 1 83 79 06 82

JAPAN

Ubisense Japan

Rakuten Crimson House

1-14-1 Tamagawa

Setagaya City Tokyo

158-0094 Japan

+81 3 4577 8372